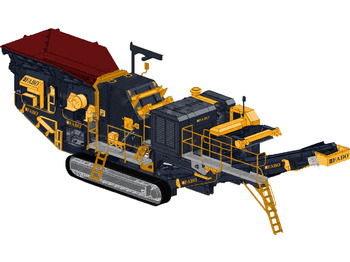

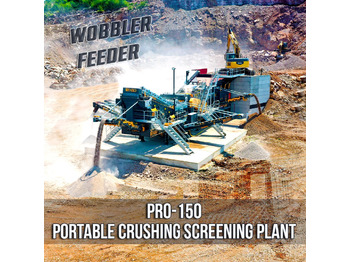

New Mining equipment FABO MOBILE CRUSHING PLANT

Published: 21d

Published: 21d

Do you need shipping?

FTC-200 Tracked Cone Crusher; It is produced in the form of feeding bunker, generator, cone crusher and stock belt.FTC-200 Tracked Cone Crusher, which is moved with a remote control on a steel track, successfully completes all commands by moving on its tracks in all difficult climatic conditions and rough terrain.FTC-200 Crawler Cone Crusher, which is delicately designed and meticulously manufactured for crushing stone, is the leading crawler crusher plant in the industry with its weight of 41,000 Kg and a crushing capacity of 100-180 T/H per hour.

Eliminates Infrastructure Requirement

FTC-200 Tracked Cone Crusher does not require an extra infrastructure as a production method, it can be moved by remote control and adapts to all difficult terrain conditions.

Belt Feeder

The Belt Feeder is the system in charge of quickly sending the loaded products to the crusher for the crushing process.It has a belt feeder motor protection system that gains mobility thanks to 2 motors. Thanks to this system, malfunctions that may occur as a result of overheating are prevented.The working intensity of the Belt Feeder and the crusher is coupled with the automation system.

This feature works in two steps.

Step 1: If the density of the crushed product in the crusher is high, the amperage of the crusher rises and this rise is detected by the automation system, the bunker transfer stops.It prevents product accumulation in the crusher feeding chute. This feature prevents the crusher from being worn out.

Step 2: If the density of the crushed product in the crusher is low, the amperage of the crusher decreases. This decrease is detected by the automation system and bunker transfer increases. The feeding hopper delivers the products to the crusher faster. This feature keeps the production capacity at the maximum level.

Cone Crusher

Cone crushers are the crusher of FTC-200 Tracked Crushing Plant that can easily crush hard stones.The power transferred from the engine to the gear shaft is sent to the hub with gears.Thanks to the core and concave inside the crusher, it crushes the stones and breaks them into pieces.

Stock Belts

With its foldable structure, it minimizes the dimensions of the machine it is on. Optionally, the number and length of tapes can be increased upon the request of the user.10 mm EP 125 4-ply Band elastics, moving on 4mm st 37 Twisted Sheet, perfectly transport the aggregate coming out of the screen to the area desired by the user in the most efficient way.Belt Elastics, which are produced resistant to wear, will never let you down and offer many years of service life.

Pallet System

The basic element that enables the movement of the FTC-200 Tracked Cone Crusher is the pallet system.Pallets carry the entire weight of the crusher.

FABO, which does not ignore the importance of the pallet system on the crushing plant, has carried out various R&D studies and has revealed the pallet system that provides maximum durability, low maintenance cost and long-term service to its user in accordance with A1 Quality CE standards.

Do you need shipping?

Get a shipping quote

Do you need shipping?

Get a shipping quote